Titanium (Ti): From Space to Earth & Back

- Sylvia Rose

- Feb 27, 2025

- 4 min read

Titanium (Ti) is a metallic element. From celestial origins titanium has widespread appeal as the metal of choice for robots, spacecraft, medical devices, cell phones, jewelry and bicycle frames.

A transition metal, titanium is known for impressive strength, low density and outstanding corrosion resistance. With an atomic number of 22, it's located in group 4 of the periodic table.

Group 4 is also known as the titanium family. Its three other members are zirconium (Zr), hafnium (Hf), and rutherfordium (Rf). Titanium displays a silver-gray color.

The global titanium market is expected to grow at a compound annual growth rate of 6.2% from 2025 to 2030. It's projected to reach USD 3.71 billion by 2030.

From Space to Earth: Arrival & Dispersal

Titanium is created eons ago within massive stars during supernova explosions. These cosmic events scatter titanium atoms across the universe. They eventually contribute to formation of planets such as Earth.

On Earth, titanium doesn't exist in a pure elemental form. It's always found combined with other elements in various minerals, primarily ilmenite (FeTiO3) and rutile (TiO2), and must be extracted.

These minerals are widely distributed in the Earth's crust, often found in igneous and metamorphic rocks, as well as in beach sands formed by the weathering of these rocks.

Ilmenite is the most important ore of titanium. It's the main source of titanium dioxide, which is used in paints, printing inks, fabrics, plastics, paper, sunscreen, food and cosmetics.

Extraction relies on the Kroll process, which reduces titanium tetrachloride (TiCl4) using magnesium to produce pure titanium. Its high reactivity means it usually exists bound within silicates and oxides.

Titanium or rainbow quartz is a specially coated type of quartz, a silicate mineral. In this human-made process quartz is put in a specialized chamber. Vaporized titanium and other metal oxides are introduced, bonding to the quartz.

Titanium Properties

Titanium's exceptional properties make it valuable for many applications.

Lightweight: It's about 45% lighter than steel but possesses comparable strength.

High Strength: Titanium boasts an impressive strength-to-weight ratio, making it ideal for applications where both strength and lightness are paramount.

High Strength-to-Weight Ratio: With a tensile strength of about 240 megapascals, titanium is four times stronger than aluminum yet only slightly heavier. It's used for aerospace applications to reduce weight.

Corrosion Resistance: Titanium forms a passive oxide layer to protect from corrosion in most environments. Titanium resists corrosion and biocorrosion in seawater.

High Melting Point: With a melting point of 1668°C (3034°F), titanium can withstand high temperatures without losing structural integrity.

Biocompatibility: Titanium is non-toxic and well-tolerated by the human body, thus suited for medical implants. Most hip replacements use titanium alloy.

Low Thermal Conductivity: Its thermal properties make titanium beneficial in applications where heat insulation is important, such as in heat exchangers.

Titanium Alloys

With over 200 different alloys available, titanium can meet specific demands in various industries. Alloys include

Aluminum: Increases strength and heat resistance while lowering weight.

Vanadium: Improves ductility and weldability.

Molybdenum: Enhances corrosion resistance and high-temperature strength, used in components like jet engines.

Iron: Provides additional hardness at lower cost.

Tantalum: Biocompatible, ideal for medical implants.

Chromium is prized for its exceptional corrosion resistance and hardness.

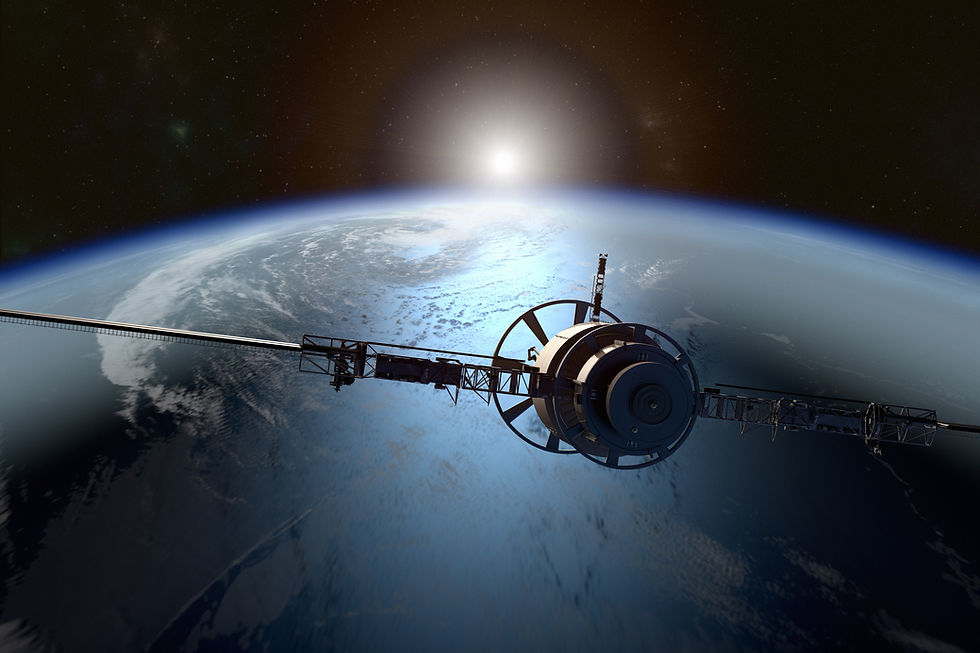

From Earth to Space: Applications

Aerospace: Aircraft engines, airframes, and spacecraft components due to its high strength-to-weight ratio and corrosion resistance. Titanium is used in aircraft components, rocket engines and space vehicles.

Medical Implants: Hip replacements, dental implants, and bone screws due to biocompatibility and resistance to corrosion. Titanium is common in implants, surgical instruments and dental materials.

Chemical Processing: Pipes, tanks, and heat exchangers in corrosive environments.

Marine Applications: Submersibles, ship hulls, and offshore platforms due to its resistance to seawater corrosion and biocorrosion.

Sporting Goods: Golf clubs, bicycle frames, and tennis rackets due to its lightness and strength.

Jewelry: From high-end sports gear to jewelry, phones and watches, titanium is chosen for its strength, lightweight nature, hypoallergenic properties and aesthetic appeal.

Industrial Equipment: Widespread in chemical processing, power generation, and the oil and gas industries, valued for durability and stability.

Facts About Titanium

Titanium can be anodized, a process that creates a colored oxide layer on its surface, adding to its aesthetic appeal.

The SR-71 Blackbird, a high-speed reconnaissance aircraft, was primarily built from titanium alloys to withstand the extreme temperatures generated during flight.

First industrial use: The first pure titanium was produced in 1910. It's not widely used until the 1940s when it gets attention in aerospace and military departments.

Non-Fiction Books:

Fiction Books:

READ: Lora Ley Adventures - Germanic Mythology Fiction Series

READ: Reiker For Hire - Victorian Detective Murder Mysteries