Silicone: Creation, Robotics & Technology

- Sylvia Rose

- Feb 26, 2025

- 4 min read

Silicone is strongly integrated into modern technology. From kitchen to electronics and self-healing robots, silicone is a human made polymer complex with many applications.

A synthetic polymer, silicone is made of silicon, oxygen, carbon, and hydrogen. Its unique chemical makeup gives it flexibility, durability, and resistance to extreme temperatures.

Depending on formulation, silicone can exist in various manifestations, including solid, liquid, or gel. Silicone gives many advantages.

Non-toxic and hypoallergenic, it's suited for food and medical use. Silicone resists ultraviolet light and ozone to maintain its quality over time. Silicone products can last up to 20 years without obvious degradation.

Unlike silicon, the semi-metallic element used in computer chips, silicone is a synthetic polymer made of repeating units of siloxane. In the siloxane unit silicon and oxygen atoms alternate in a chain, with organic groups attached to the silicon atoms.

The production of silicone begins with silica sand (silicon dioxide SiO2). The sand is reacted with carbon at extremely high temperatures in an electric arc furnace. This process yields silicon metal.

The silicon metal then reacts with methyl chloride in the presence of copper as a catalyst, producing a mixture of methylchlorosilanes. In a reaction with water, chlorine atoms are replaced by hydroxyl groups (OH).

The resulting compound is silanol ([CH3]2Si[OH]2). It polymerizes in a condensation reaction to create siloxanes.

Siloxane is a functional group consisting of silicon (Si), oxygen (O), and carbon-containing compounds. The general formula for siloxane is R2SiO, where R can be a variety of groups.

Silicone includes silicones, or polymers made up of siloxane. Type and length of siloxane chains, and organic groups attached to silicon atoms, determine specific properties and characteristics of the resulting silicone.

Characteristics: Versatility of Silicone

High Thermal Stability: Silicone remains stable and retains its properties over a wide range of temperatures from -55°C to 300°C (-67°F to 572°F).

Chemical Resistance: Silicone is resistant to many chemicals, including acids, bases, and solvents, thus ideal for harsh environments. It's used in aerospace products and industrial machinery.

Electrical Insulation: Silicone is a good insulator, preventing the flow of electricity and making it useful in electrical applications.

Water Repellent: Silicone has hydrophobic properties, meaning it repels water and is resistant to moisture.

Flexible and Elastic: Depending on formulation, silicone is very flexible and elastic, suitable for sealing, cushioning, and vibration dampening. Silicone maintains flexibility over time. Silicone rubber seals in cars can (potentially) last the life of the vehicle.

Biocompatibility: Silicone is generally non-toxic and biocompatible. It can be used in medical implants, prosthetics and other products in contact with the human body.

Weather Resistance: Silicone is resistant to degradation from UV radiation, ozone, and other environmental factors, making it durable for outdoor applications.

Food Safety: Silicone does not leach harmful chemicals, making it suitable for food-grade utensils.

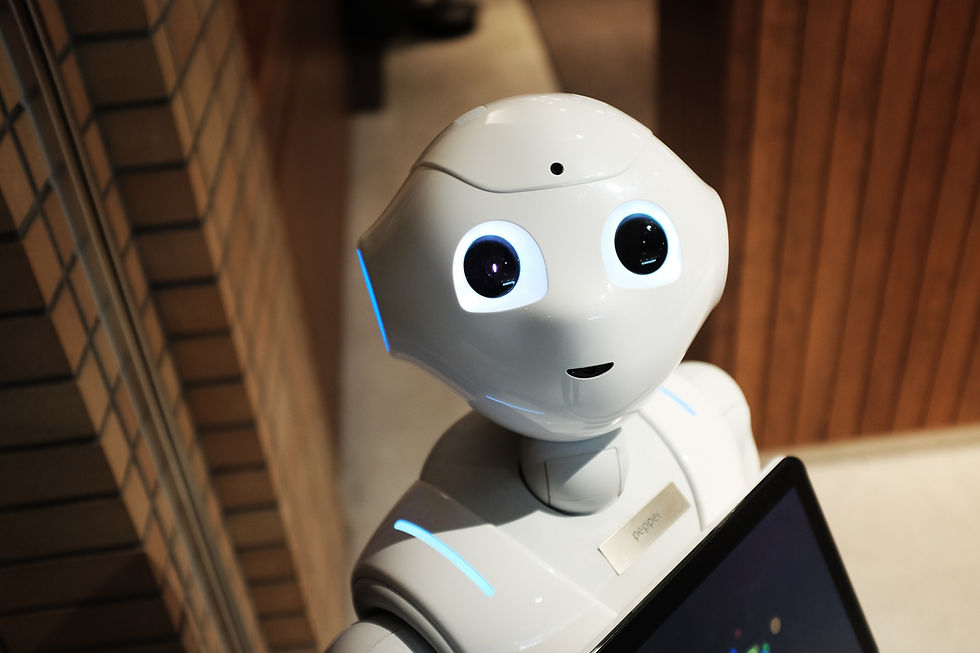

Silicone in Robots and Technology

Robotic Skin and Actuators: Silicone creates soft, flexible robotic skin to mimic the feel and movement of human skin. Silicone is used in soft robotics, enabling the creation of flexible actuators and grippers.

Soft robots can navigate tricky terrains by mimicking movements of worms and octopuses. Silicone-based actuators allow soft robots to interact with greater sensitivity to their surroundings.

Electronics Protection: Silicone is used to encapsulate and protect sensitive electronic components from moisture, dust, and vibration especially in hostile environments.

Seals and Gaskets: Silicone's sealing properties make it ideal for creating seals and gaskets in electronic devices and robotic systems.

Adhesives and Bonding: Silicone adhesives are used to bond different materials together in electronic devices and robots. They provide a strong, durable bond to withstand high temperatures and vibrations.

Medical Implants and Devices: Due to its biocompatibility, silicone is widely used in medical implants, such as breast implants and pacemakers. It's also used in medical devices like catheters and tubing.

Wearable Technology: Silicone is a popular material for wearable technology, such as smartwatches and fitness trackers, due to its flexibility, durability, and water resistance.

Silicone is used in for sensors for data collection. For instance a small, flexible sensor encased in silicone is used in temperature monitoring for patients recovering from surgery.

Advanced robotics: Silicone aids development of sophisticated human-like robots. Silicone's biocompatibility and flexibility can be used to create electronic devices which can be seamlessly integrated with the human body.

Renewable energy technologies: Silicone is used in solar panels and other renewable energy technologies.

Its thermal stability ensures reliability in devices like smartphones and laptops. Silicone is used in over 90% of smartphones for its insulating properties. In 3D printing, silicone enables creation of flexible components.

Non-Fiction Books:

Fiction Books:

READ: Lora Ley Adventures - Germanic Mythology Fiction Series

READ: Reiker For Hire - Victorian Detective Murder Mysteries