Building Robots: Elastomers, Metals & Plastics

- Sylvia Rose

- Feb 27, 2025

- 3 min read

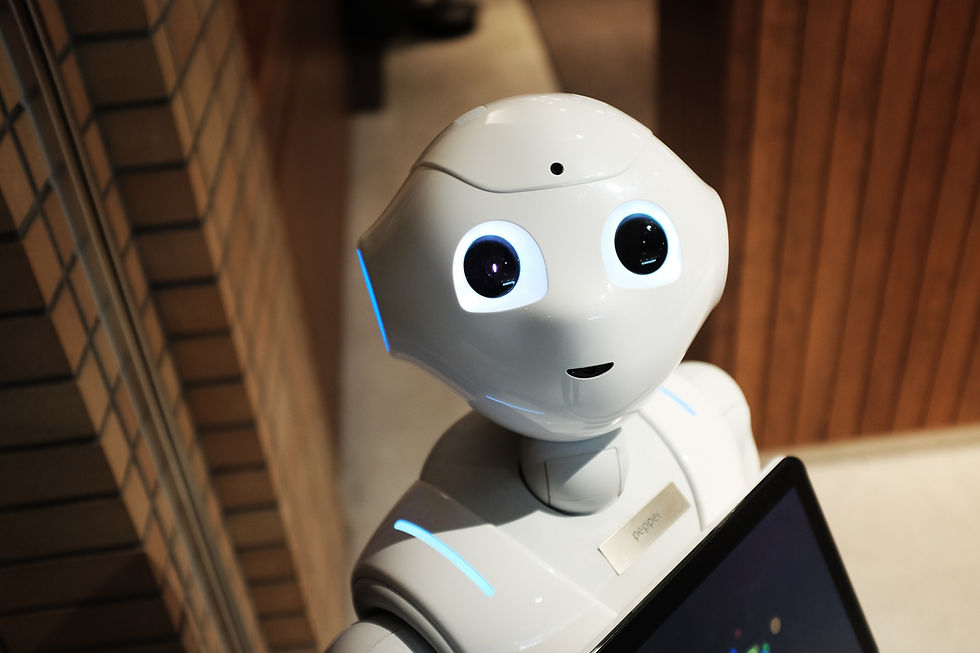

Building robots is a mix of engineering, technology, and creativity. Metals and plastics are the standout choices for roboticists. Elastomers provide flexibility, and polymers like self-healing silicone tweak popular interest.

Certain materials are desired for their unique properties. While the specific choice depends on the robot's intended function and environment, metals, plastics, and elastomers are favored materials for robotic construction.

Metals

Aluminum: Lightweight yet strong, aluminum has a good strength-to-weight ratio. It's a popular choice for robots requiring agility and speed, such as those used in manufacturing or search and rescue operations.

Its corrosion resistance is also a valuable asset, extending robot lifespan in various environments. Drones, which can weigh less than 5 kg, benefit greatly from aluminum, facilitating more agile flight.

Steel: Renowned for high tensile strength and resistance to wear and tear, steel provides structural integrity. It's suitable for robots designed for heavy-duty tasks, such as construction, mining, or industrial welding.

Steel is used in critical components like robot frames and support beams. Industrial robots with steel frames support loads of over 500 kg. Variants like stainless steel fortify corrosion resistance.

Titanium: Titanium has high strength-to-weight ratio and superior corrosion resistance. While more expensive than aluminum or steel, its performance makes it suited for aerospace, underwater exploration or surgical robotics.

Plastics

Plastics reduce weight, promote versatility and optimize specific functions. Their moldability enables complex geometries and intricate designs. They're ideal for housings, covers, and specialized components.

Plastics offer several advantages.

Lightweighting: Plastics reduce overall weight of the robot, improving agility, power efficiency and payload capacity. This is important for mobile robots and those designed for human interaction.

Electrical Insulation: Plastics are inherently electrically insulating, protecting sensitive electronic components from short circuits and ensuring safe operation.

Ease of Manufacturing: Plastics can be easily molded, cast, and machined, allowing for rapid prototyping and cost-effective production of complex parts.

Specific Properties: Plastics offer diverse properties, such as high impact durability, chemical resistance or transparency. These allow engineers to refine material selection to their requirements.

Polycarbonate is often used for protective enclosures due to its exceptional impact strength. Acrylic works well for transparent covers and displays.

High-performance plastics, such as polycarbonate, are often included in protective housings for sensitive electronic components. In robotic arms used for surgery, polycarbonate casings protect circuitry while enabling lightweight functionality.

Elastomers

Elastomers or rubber-like materials are important in soft robotics. This field focuses on creating robots which adapt to environments better than rigid models, for example moving like an octopus to navigate narrow spaces.

Elastomers create robots with unprecedented flexibility, adaptability and dexterity. Unlike traditional rigid robots, soft robots can bend, twist, and conform to their environment.

They can carry out delicate tasks, grasp irregularly shaped objects, and absorb impacts without damage.

Biomimicry: Soft robots are inspired by biological systems, mimicking the movements and capabilities of creatures like octopuses, worms, and jellyfish.

Applications: Soft robotics has applications in diverse fields, including medical devices, search and rescue operations, agriculture and space exploration. Soft robotics can enhance military and medical exosuits.

Other Robot Materials

Composites: Combining strength of fibers with lightweight properties of polymers, composites have high strength-to-weight ratios and can be refined to specific applications. These hybrid materials produce strong and agile systems.

Shape Memory Alloys: These materials can deform and return to their original shape when exposed to heat, offering unique possibilities for actuation and sensing in robots.

Self-Healing Materials: Materials that can automatically repair damage, extending the lifespan of robots and reducing maintenance costs.

Non-Fiction Books:

Fiction Books:

READ: Lora Ley Adventures - Germanic Mythology Fiction Series

READ: Reiker For Hire - Victorian Detective Murder Mysteries